Mailbox:

info@hskcoltd.com

Mailbox:

info@hskcoltd.com

Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Email: info@hskcoltd.com

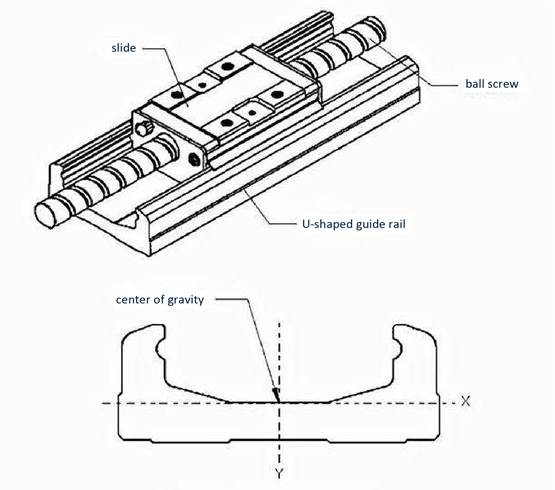

The guide rail in the linear module is combined with the base to form a U-shaped structure, which is called U-shaped guide rail. It has the functions of space saving, high stiffness, high precision and simplifying parts. It can provide relative lightweight and become a high-precision positioning platform. Space saving: Although the assembly interface has the same size as similar products, the u-guide looks smaller and has less space; such an arrangement can make the center of gravity of the U-shaped guide rail fall at the bottom. Strong rigidity: through the optimized design of finite element method, the stiffness of U-shaped guide rail can also be improved simultaneously. High precision positioning platform: precision positioning is achieved by the stiffness of the rails and bearings for precision U-shaped guide rail and ball screw.

How to connect the motor terminals?

Servo and stepping motors on the market can be selected as the driving motor terminals, and there are some small differences in the shape and size of each brand. The connection mode is using the motor terminal to connect flange, mounted on the precision linear module, and driving the ball screw to move the slide table directly through the coupling. You can also select the rotating motor to connect flange and move the slide with a girdle. Low inertia servo motor is very suitable for precision linear module, which can have high speed and high precision. When using stepping motor, micro stepping driver is adopted, with relatively improved resolution, low unit price and high positioning accuracy.

How to install?

Simplify the standard module design and installation interface. It is quite easy to use the linear module, lock the relevant workpiece, and high-precision linear transmission applications can be set up without complex adjustment procedures. In order to make the installation more convenient for users, a reliable surface of assembly is arranged on the U-shaped guide rail and slide seat, so that the accuracy requirements of assembly can be easily met.

Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Email: info@hskcoltd.com

Follow us

Copyright ? 2021 Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Mailbox