Mailbox:

info@hskcoltd.com

Mailbox:

info@hskcoltd.com

Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Email: info@hskcoltd.com

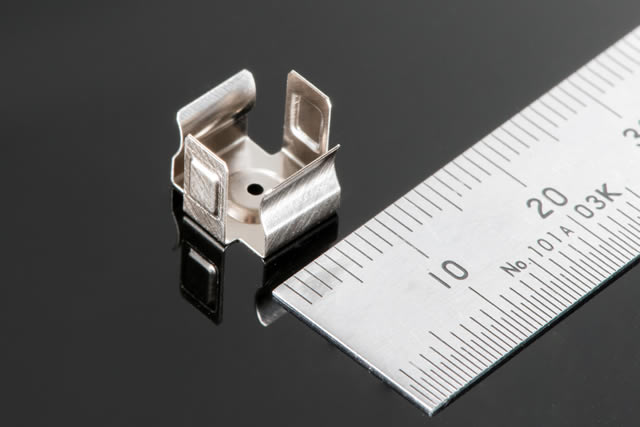

Metal stamping processing is a common way of metal processing. What are the factors that affect the processing quality of metal stamping? How do we choose or avoid some common problems? Compared with other processing methods, metal stamping parts have advantages in skills and economy.

There are many factors that affect the forming and quality accuracy of metal stamping parts, such as die structure design and die accuracy. Die manufacturing cost and life are important factors that affect the cost and quality of stamping parts. More time is needed for the design and manufacture of the die, which extends the production preparation time of the metal stamping parts.

Stamping can produce workpieces with steel, ribs, curls or flanging, which is difficult to manufacture in skilled hands, so as to improve its rigidity. Metal stamping parts, castings and forgings have the characteristics of thin, uniform, light and strong.

In actual production, process experiments similar to the stamping process, such as drawing function experiment and expansion function experiment, are usually used to test the stamping function of materials to ensure product quality and high qualified rate. Mainly due to the rejection of rough molds, the workpiece accuracy can reach the micron level, with high accuracy and universal standards. It can punch holes, bosses, etc.

With the rapid development of the times, machinery should also keep pace. With the development of lightweight automobile and metal machinery products, metal processing technology is also getting better. All kinds of products put forward higher and higher requirements for the number, life and disorder of die-casting dies.

Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Email: info@hskcoltd.com

Follow us

Copyright ? 2021 Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Mailbox