Mailbox:

info@hskcoltd.com

Mailbox:

info@hskcoltd.com

Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Email: info@hskcoltd.com

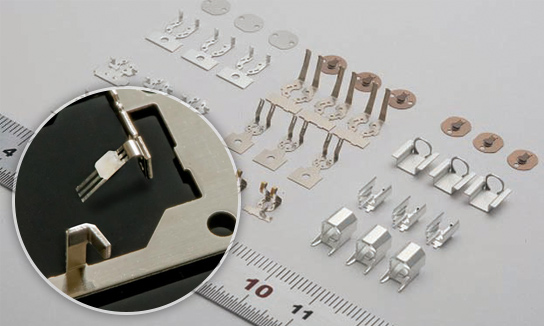

In the intricate world of consumer electronics, precision stamping plays a pivotal role, ensuring the creation of complicated components that power our devices. Hashimoto Precision stands at the forefront of this industry, renowned for delivering exceptional consumer electronics precision stamping services that uphold the highest standards of quality and innovation.

The Essence of Consumer Electronics Precision Stamping

Consumer electronics precision stamping involves the meticulous fabrication of intricate metal components integral to various electronic devices' functionality. These components are often found in smartphones, wearable gadgets, and even household appliances. The significance of precision stamping lies in its ability to create parts with unparalleled accuracy, durability, and efficiency. Hashimoto Precision, a distinguished name in the manufacturing domain, takes pride in offering cutting-edge solutions that cater to the unique demands of consumer electronics.

Navigating the Steps of Consumer Electronics Precision Stamping

The journey of consumer electronics precision metal stamping encompasses intricate steps, each contributing to the final product's excellence. From initial design and engineering to the ultimate packaging and distribution, every stage is executed with utmost precision.

Hashimoto Precision’s process includes design and engineering, material selection, die design and fabrication, material preparation, feeding and clamping, stamping, forming and blanking, trimming and piercing, bending and folding, quality control, surface treatment, assembly and integration, testing, and finally, packaging and distribution.

Applications Unveiled

The applications of consumer electronics precision stamping are diverse and far-reaching. Utilizes its expertise, Hashimoto Precision has created critical components such as voice coils, tiny microphones, speakers, transmitters, and receivers. These elements are the backbone of devices that enhance communication, entertainment, and convenience.

1. Voice Coils: Precise voice coils are essential for converting electrical signals into clear and crisp sound, making them indispensable in speakers and headphones.

2. Tiny Microphones: The minuscule microphones produced through precision stamping enable advanced voice recognition and crystal-clear audio capture in various electronic devices.

3. Speakers: Precision-stamped components are vital in producing speakers that offer exceptional audio quality and immersive experiences across diverse devices.

4. Transmitters and Receivers: Wireless communication owes its efficiency to the precision-stamped transmitters and receivers that facilitate seamless data exchange in devices like smartphones and wireless earbuds.

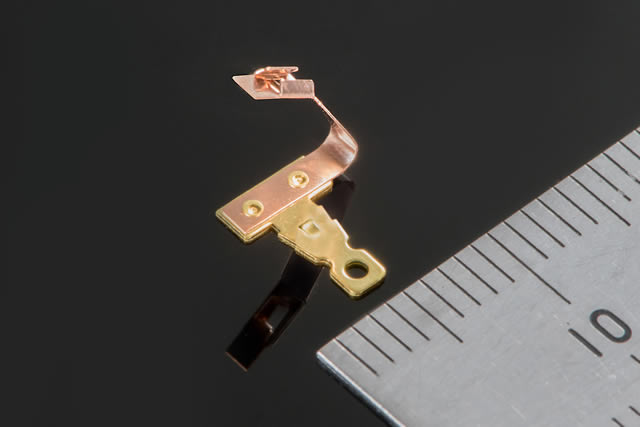

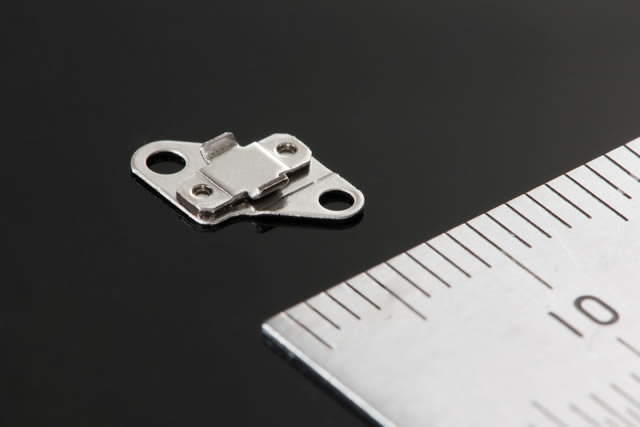

Crafting with Care – Materials in Consumer Electronics Precision Stamping

Hashimoto Precision employs an array of premium materials to create components that meet the highest industry standards:

- Copper Alloy: Known for its excellent conductivity and malleability, copper alloy components ensure reliable electronic connections.

- Stainless Steel Alloy: Renowned for its durability and resistance to corrosion, stainless steel alloy is used to craft robust and long-lasting components.

- High Nickel Alloy: This alloy offer exceptional strength and heat resistance, making them ideal for components that operate under demanding conditions.

- Aluminum Alloy: Lightweight and corrosion-resistant, aluminum alloy components find their place in consumer electronics.

- Tinplate: Tinplate's unique properties make it a suitable choice for components that require both strength and a protective surface.

- PET (Polyethylene Terephthalate): PET is utilized for insulating and protective components due to its electrical insulation properties and durability.

Conclusion

Consumer electronics precision stamping is a cornerstone of modern device manufacturing. Hashimoto Precision's dedication to excellence is evident through our meticulous approach to each process step. Our mastery of materials and commitment to innovation allows us to craft components that fuel electronic experiences.

Hashimoto Precision emerges as a beacon of excellence in the world of consumer electronics precision stamping suppliers. Our steadfast commitment to quality, innovation, and precision ensures that every component manufactured under our banner is a testament to our expertise. As you delve into consumer electronics, exploring Hashimoto Precision's offerings is a journey toward discovering cutting-edge solutions that power the devices we rely on daily.

Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Email: info@hskcoltd.com

Follow us

Copyright ? 2021 Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Mailbox